Alternations in Helmholtz resonator neck angle and the shape of its connection to the air channels to increase the insertion loss of sound

Keywords:

Helmholtz resonator Insertion loss of sound (IL) Neck angle of resonator Shape of resonator neckAbstract

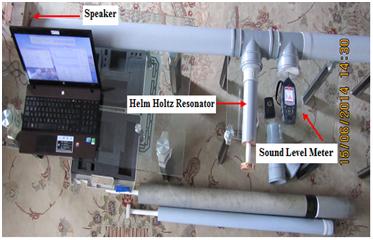

Different methods of sound control in industry have been investigated by the researchers. The passive methods such as membrane absorbents, porous absorbents and the sound resonators are among the most important methods of sound control and reduction. In the present study, the effects of changing Helmholtz resonator neck angle relative to the sound channel along with the other alternations in geometric properties of the resonator such as length, cross section and the shape of the cross section were investigated. The circular and rectangular necks with various lengths and shape were used for finding the changes of insertion loss in a cylinder shaped channel made out of PVC with 3 m long and diameter of 9 cm and the thickness of 2.7 mm. The level of insertion loss of sound would be higher in comparison with 45 and 90 degree angles. The rectangular shaped neck exhibited the least efficiency in sound reduction while the conical shaped neck whose base attachment to the sound channel has circular shape resulted in highest level of sound dissipation. The shorter necks with larger cross sections, in comparison with longer necks with small cross sections, would lead to higher insertion loss of sound.

References

Bistafa, S.R., Hodgkin, M.P., Morita, W.S., Köhn, B.O., Neto, J.J., 2012. Adaptive control of low-frequency acoustic modes in small rooms. Open. Acoust. J. 5, 16-22.

Bothien, M.R., Wassmer, D., Impact of density discontinuities on the resonance frequency of Helmholtz resonators. AIAA journal. 2015, 1-11.

Changbin, G., Zongxia, J., 2012. Modeling and optimal design of 3 degrees of freedom Helmholtz resonator in hydraulic system. Chin. J. Aeronaut. 25(5), 776-83.

Chatellier, L., Laumonier, J., Gervais, Y., 2004. Theoretical and experimental investigations of low Mach number turbulent cavity flows. Experiments in fluids. 36(5), 728-40.

Chen, K., Chen, Y., Lin, K., Weng, C., 1998. The improvement on the transmission loss of a duct by adding Helmholtz resonators. Appl. Acoust. 54(1), 71-82.

Cherrier, O., Pommier-Budinger, V., Simon, F., 2012. Panel of resonators with variable resonance frequency for noise control. Appl. Acoust. 73(8), 781-90.

Cox, T.J., D'antonio, P., 2009. Acoustic absorbers and diffusers: theory, design and application: CRC Press.

De Bedout, J.M., 1996. Adaptive-passive noise control with self-tuning Helmholtz resonators: Citeseer.

de Jong, A.T., Bijl, H., Scarano, F., 2011. The aero-acoustic resonance behavior of partially covered slender cavities. Experiments in fluids. 51(5), 1353-67.

De Salis, M., Oldham, D., Sharples, S., 2002. Noise control strategies for naturally ventilated buildings. Building and Environment. 37(5), 471-84.

Dequand, S., Hulshoff, S., Kuijk, H.V., Willems, J., Hirschberg, A., 2003. Helmholtz-like resonator self-sustained oscillations, part 2: detailed flow measurements and numerical simulations. AIAA journal. 41(3), 416-23.

Esteve, S.J., Johnson, M.E., 2005. Adaptive Helmholtz resonators and passive vibration absorbers for cylinder interior noise control. J. Sound. Vib. 288(4), 1105-30.

Griffin, S., Lane, S.A., Huybrechts, S., 2001. Coupled Helmholtz resonators for acoustic attenuation. J. Vib. Acoust. 123(1), 11-7.

Kook, H., Mongeau, L., Franchek, M., 2002. Active control of pressure fluctuations due to flow over Helmholtz resonators. J. sound. vib. 255(1), 61-76.

Li, Y., 2010. Noise control of an acoustic enclosure covered by a double-wall structure with shallow gap: Design of resonator-like cavities. Appl. Acoust. 71(7), 675-80.

Liu, Z., Hill, D.L., Editors, 2001. Centrifugal compressor noise reduction by using Helmholtz resonator arrays. Proceedings of the 30th Turbomachinery Symposium.

Ma, R., Slaboch, P.E., Morris, S.C., 2009. Fluid mechanics of the flow-excited Helmholtz resonator. J. Fluid. Mech. 623, 1-26.

Monkewitz, P.A., Nguyen-Vo, N.M., 1985. The response of Helmholtz resonators to external excitation. Part 1. Single resonators. J. Fluid. Mech. 151, 477-97.

Nair, S.U., Shete, C., Subramoniam, A., Handoo, K., Padmanabhan, C., 2010. Experimental and computational investigation of coupled resonator–cavity systems. Appl. Acoust. 71(1), 61-7.

Passchier-Vermeer, W., Passchier, W.F., 2000. Noise exposure and public health. Environmental health perspectives, 108(Suppl 1), 123.

Peat, K., 2010. Acoustic impedance at the interface between a plain and a perforated pipe. J. Sound. Vib. 329(14), 2884-94.

Pourtaghi, G., Mokarami, H., Valipour, F., Ghasemi, M., 2014. Prevention of noise damages causes by shooting fire of Kalashnikov (AK-47) rifle by regulation of suitable distance. Sci. J. Pure. Appl. Sci. 3(3), 128-34.

Selamet, A., Kothamasu, V., Novak, J., 2001. Insertion loss of a Helmholtz resonator in the intake system of internal combustion engines: an experimental and computational investigation. Appl. Acoust. 62(4), 381-409.

Selamet, A., Xu, M., Lee, I.J., Huff, N., 2005. Helmholtz resonator lined with absorbing material. J. Acoust. Soc. Am. 117(2), 725-33.

Shi, X., Mak, C.M., Yang, J., 2013. Attenuation performance of a semi-active Helmholtz resonator in a grazing flow duct.

Sun, H., Shin, H., Lee, S., 2006. Analysis and optimization of aerodynamic noise in a centrifugal compressor. J. Sound. Vib. 289(4), 999-1018.

Tang, S., 2005. On Helmholtz resonators with tapered necks. J. Sound. Vib. 279(3), 1085-96.

Utsumi, M., 2001. Reduction of noise transmission in a duct by termination impedance control of a sidebranch resonator. J. Vib. Acoust. 123(3), 289-96.

Yasuda, T., Wu, C., Nakagawa, N., Nagamura, K., 2013. Studies on an automobile muffler with the acoustic characteristic of low-pass filter and Helmholtz resonator. Appl. Acoust. 74(1), 49-57.

Z M. 2004. Environmental and Architectural Acoustics: CRC Press.

Zhao, D., Morgans, A.S., 2009. Tuned passive control of combustion instabilities using multiple Helmholtz resonators. J. sound. vib. 320(4), 744-57.

Zhao, S., Wang, J., Wang, J., He, Y., 2006. Expansion-chamber muffler for impulse noise of pneumatic frictional clutch and brake in mechanical presses. Appl. Acoust. 67(6), 580-94.

Published

How to Cite

Issue

Section

Copyright (c) 2020 Gh. Pourtaghi, F. Valipour, H. Mokarami, R. Ataeifarid

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.